Medical silicone hose is a kind of hose used for medical purposes. Medical silicone hose, cold and high temperature resistance, weak acid and alkali resistance, harmless, non-toxic and tasteless; high transparency, high elasticity, strong UV resistance; good elasticity, resistance to kink and no deformation, soft, arc resistance, corona resistance, chemical stability , Physiologically inert, non-toxic and non-irritating to the human body, hydrophobic, breathable, excellent resilience, long-term non-deformation, etc., can be used at -50 degrees to 250 degrees, special requirements for accessibility, excellent insulation, in Ethylene oxide can be used for disinfection under high temperature conditions. It meets the food and drug testing standards. It will not yellow, bloom, spit white, or fade when placed at room temperature, and will not have scale in the water for a long time.

Appearance inspection standard of medical silicone hose:

1. Silicone tube color

(1). Standard: The silicone is not exposed after vulcanization and assembly, and there is no big difference.

(2). Detection method: under bright natural light or 40W fluorescent lamp, put the standard sample or color card and the sample to be calibrated together, with a visual acuity of 1.0 or more, and a color-blind professional with a 30cm distance between the naked eye and the sample Check visually for 5 seconds.

2. Medical silicone hose eccentric

(1) Standard: H thick-H thin, when the elastic wall thickness is less than or equal to 0.1MM, X=20℅ during mold inspection;

When the elastic wall thickness is less than or equal to 0.2MM, X=15℅ during mold inspection

H thick H thin when the elastic wall thickness is less than or equal to 0.3MM, X=8% during mold inspection

(2) Detection method: test with thickness meter.

3.

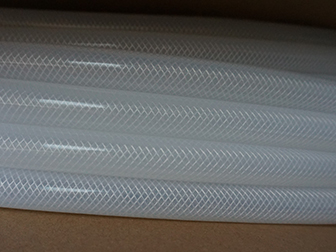

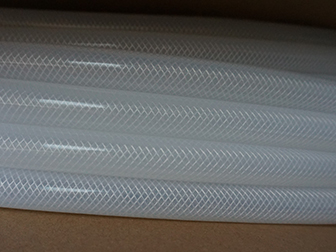

Medical braided silicone hose overflow

(1) Standard: From the key surface down, the height of the single color material is greater than or equal to the height of the exposed shell 1.0MM, and it is better to be invisible after installing the shell

(2) Detection method: measure with vernier caliper

4. Raw edges

(1) Standard: positioning hole: ≤0.1MM product edge: ≤0.5MM

5. Rupture

(1) Standard: No impact on assembly and use performance: ≤1.0MM

(2) Detection method: measure with vernier caliper

6. Color dots and bumps

(1) Standard: The exposed part of the silicone after the customer assembly: No obvious visible

(2) Detection method: under bright natural light or 40 watt fluorescent lamp, the sample is placed about 30 cm away from the naked eye and visually inspected by a person with a vision of 1.0 or more for 5 seconds.

Custom silicone hose is available. SUNRISE can produce suitable hoses according to your needs. Welcome to SUNRISE to inquiry and order!

Related Products: Platinum Silicone Tubing,Braid Reinforced Silicone Hose